keywords | membrane-based system | module fabrication | CO2 gas removal | porous polyvinylidene fluoride (PVDF) |

PRODUCT DESCRIPTION / FEATURES

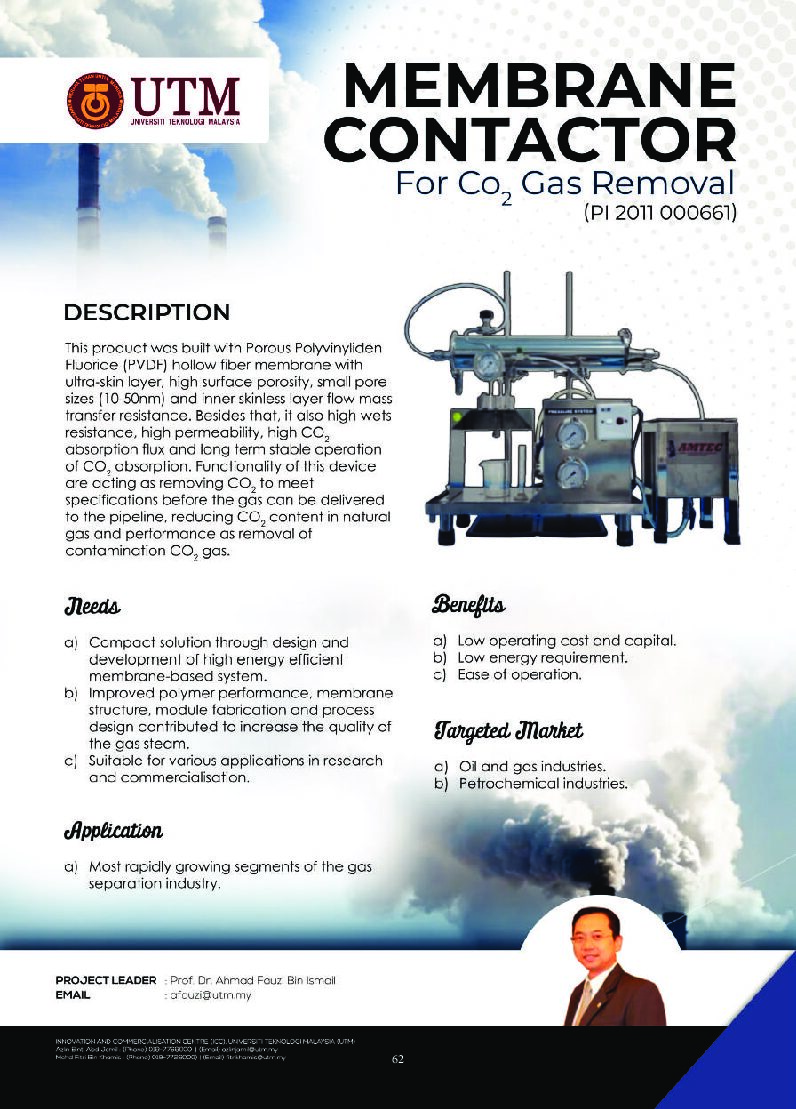

This product was built with Porous Polyvinylidene Fluoride (PVDF) hollow fiber membrane with ultra-skin layer, high surface porosity, small pore sizes (10-50nm), and inner skinless layer flow mass transfer resistance. Besides that, it is also high wets resistance, high permeability, high CO2 absorption flux, and long term stable operation of CO2 absorption. The functionality of this device is acting as removing CO2 to meet specifications before the gas can be delivered to the pipeline, reducing CO2 content in natural gas and performance as removal of contamination CO2 gas.

NEEDS

Compact solution through design and development of high energy efficient membrane-based system.

Improved polymer performance, membrane structure, module fabrication, and process design contributed to increasing the quality of the gas steam.

Suitable for various applications in research and commercialization.

APPROACH

Most rapidly growing segments of the gas separation industry.

BENEFITS

Low operating cost and capital.

Low energy requirement.

Ease of operation.

COMPETITORS

Most rapidly growing segments of the gas separation industry, Oil and gas, or petrochemical induslries.

PROJECT LEADER

Prof. Dr. Ahmad Fauzi Ismail

afauzi@utm.my